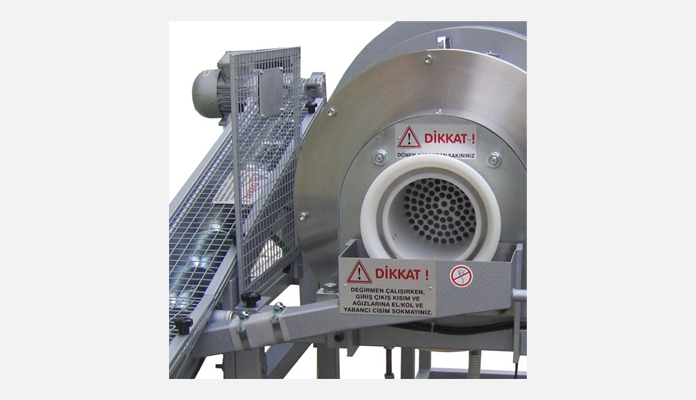

It is for pilot plant and small industrial size grinding applications. Suitable for both wet and dry grinding.

It is for pilot plant and small industrial size grinding applications. Suitable for both wet and dry grinding.

- Driven by a 4 kW, 1450 rpm, 380 V, 3 p, 50 Hz electrical motor and a gearbox at 50 rpm grinding speed

- 100 L capacity Ø500×500 mm grinding mill made of AISI 304 Stainless Steel

- Ø160 mm circular openings on both ends provided with Ø12 mm perforated circular plates to keep ball charge inside the mill

- A rubber gasketed 150×125 mm lid on lateral side for easy ball charge loading/unloading, washing and cleaning purposes

- A Ø150×1500 mm spiral classifier for continuous wet closed circuit grinding

- A magnetic vibratory feeder for infinitely variable raw material feeding

- Provided with a charge of hardened steel balls

- Easy and safe operation, maintenance and cleaning facility.

- The horizontal grinding axes of the mill can easily be tilted (infinitely variable) by a screw angular adjustment system

- Feeding Size: < 6,35 mm

- Grinding Capacity: 100 kg/h *

* Approx. capacity based on wet grinding medium hard ore, -6,35 mm feed, –212 µm product size.

Unleashing Efficiency: Ball Mill with Closed Circuit Spiral Classifier

When it comes to mineral processing and the reduction of particle sizes, a Ball Mill combined with a Closed Circuit Spiral Classifier stands as an unbeatable solution. This dynamic duo has revolutionized the industry, delivering precise classifications and grinding capabilities for optimal results.

Understanding the Ball Mill and Closed Circuit Spiral Classifier

A Ball Mill is a grinding machine used to grind, blend, and sometimes for mixing materials for use in mineral dressing processes. The grinding media are the balls, which may be made of steel, stainless steel, ceramic, or rubber.

Working alongside the Ball Mill is the Spiral Classifier. A Spiral Classifier helps to separate the ball mill discharge into overflow (fine particles) and underflow (coarse particles). The setup becomes a ‘closed circuit’ when the mill and the classifier work continuously, with the underflow returning to the mill for further grinding.

The Power of the Duo

The combination of a Ball Mill with a Closed Circuit Spiral Classifier ensures an efficient grinding and classification process. This system not only grinds the material to the desired particle size but also ensures the removal of unwanted oversized particles.

Choosing the Right Ball Mill with Closed Circuit Spiral Classifier

Selection of the right setup depends on several factors such as the nature of the material, desired particle size, throughput, and specific energy consumption. Trusted brands provide customizable solutions that can be tailored according to your needs, offering better control and consistency in product quality.

The Future of Ball Mills with Closed Circuit Spiral Classifiers

With technological advancements, Ball Mills and Spiral Classifiers are expected to evolve. Future models may incorporate real-time analytics, increased automation, and improved energy efficiency, making them even more vital in mineral processing and other industrial applications.

Conclusion

For precise particle size reduction and efficient classification, the combination of a Ball Mill with a Closed Circuit Spiral Classifier is a significant game-changer. This pair not only enhances productivity but also ensures the consistent quality of the final product.