Laboratory Crushers and Pulverizers: Essential Tools for Efficient Sample Preparation in Mining

In the mining industry, accurate and efficient sample preparation is crucial for obtaining reliable analytical results. Laboratory crushers and pulverizers are essential tools in this process, designed to reduce the size of mineral samples and create uniform particle sizes for analysis. In this article, we will discuss the importance of laboratory crushers and pulverizers in the mining industry, their various types, and how they contribute to the accuracy and efficiency of mineral analysis.

Significance of Laboratory Crushers and Pulverizers in Mining Sample Preparation

- Consistent Particle Size: Laboratory crushers and pulverizers are designed to produce uniform particle sizes, which is crucial for ensuring the accuracy and consistency of mineral analysis. By reducing the mineral samples to a consistent size, these machines help eliminate discrepancies that may arise from variations in particle size distribution.

- Enhanced Analytical Accuracy: Accurate sample preparation is essential for obtaining reliable results in mineral analysis. Laboratory crushers and pulverizers help achieve this by ensuring that mineral samples are prepared in a consistent and standardized manner, reducing the likelihood of errors and improving the overall accuracy of analytical results.

- Improved Efficiency: By automating the sample preparation process, laboratory crushers and pulverizers help increase efficiency in mining operations. These machines can process large quantities of samples quickly and consistently, reducing the time and effort required for sample preparation.

- Reduced Contamination: Laboratory crushers and pulverizers are designed to minimize the risk of contamination during the sample preparation process. Their construction materials, such as stainless steel or tungsten carbide, resist wear and contamination, ensuring that samples remain free of impurities that may impact the accuracy of analytical results.

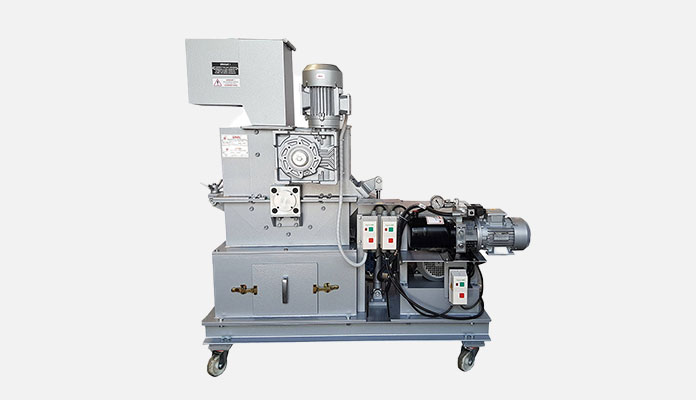

Types of Laboratory Crushers and Pulverizers

Jaw Crushers: Jaw crushers are designed to reduce the size of large rocks or ores by compressing them between two jaws—one fixed and the other moving. They are ideal for primary crushing of hard and brittle materials, producing a coarse output size suitable for further processing.

Cone Crushers: Cone crushers are used for secondary or tertiary crushing, reducing the size of mineral samples further by compressing them between an eccentrically rotating cone and a fixed outer shell. They are suitable for processing a wide range of materials, including hard, abrasive rocks and ores.

Roll Crushers: Roll crushers consist of two or more cylindrical rollers that rotate in opposite directions, crushing the sample between them. They are designed for intermediate crushing of friable materials, producing a medium output size. Roll crushers can be used for both primary and secondary crushing, depending on the application.

Hammer Mills: Hammer mills use rotating hammers to crush the mineral samples against a stationary grinding surface. They are ideal for crushing soft to medium-hard materials, producing a fine output size suitable for analysis.

Disc Mills: Disc mills consist of two counter-rotating discs with ridges or teeth that crush the mineral samples by shearing and grinding actions. They are suitable for processing a wide range of materials, from soft to hard, and produce a fine output size ideal for analysis.

Ball Mills: Ball mills are used for fine grinding of mineral samples, using grinding media (such as balls) to crush the sample against the inner wall of the mill. They are suitable for processing a wide range of materials and produce a fine output size suitable for analysis.

Laboratory crushers and pulverizers play a vital role in the mining industry by ensuring accurate and efficient sample preparation for mineral analysis. By providing consistent particle sizes, enhancing analytical accuracy, improving efficiency, and reducing contamination risks, these machines contribute to the overall success of mining operations. As the mining industry continues to evolve and prioritize innovation, laboratory crushers and pulverizers will remain indispensable tools for obtaining reliable and accurate analytical results, ensuring the long-term viability and efficiency of mining operations worldwide.