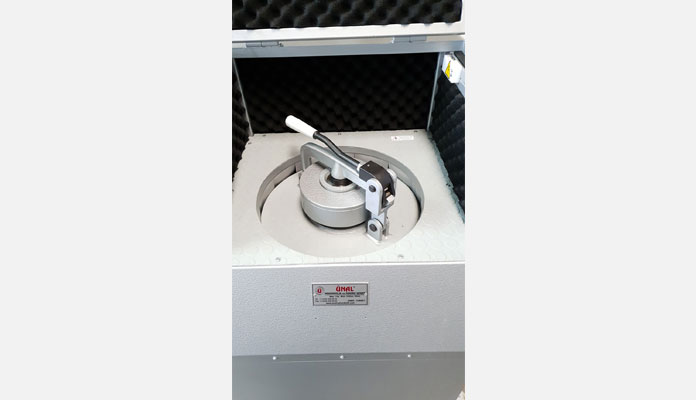

Laboratory Type Vibratory Disc Mill

The Vibratory Disc Mill is used for the very rapid, safe and efficient grinding of medium-hard, hard, brittle and tough materials. It is a very useful for sample preparation in laboratories and industrial plants.

Product Description

The Vibratory Disc Mill is used for the very rapid, safe and efficient grinding of medium-hard, hard, brittle and tough materials. It is a very useful for sample preparation in laboratories and industrial plants.

Application Examples: Alloys, basalt, cement clinker, ceramics, chamotte, coal, coke, construction materials, feldspar, glass and various materials.

- CE Marked

- Electrical Motor: 1,5 HP, 1000 rpm, 380 V, 3 p, 50Hz

- Grinding Set Sizes : 400 cc, 250 cc, 100 cc, 50 cc

- Feed Quantity: 35-200 ml

- Feeding Size: < 15 mm*

- Final Fineness: < 38 μm*

- Dijital setting of grinding time from 0 up to 999 h or 999 min. or 999 seconds

The Powerhouse of Milling: The Vibratory Disc Mill

When it comes to the world of sample preparation and lab testing, nothing beats the efficiency and precision of a Vibratory Disc Mill. These high-performance mills are essential components in laboratories across the globe, especially for geological, metallurgical, and building material applications.

Understanding the Vibratory Disc Mill

A Vibratory Disc Mill is a type of milling and grinding equipment. Its primary function is to reduce solid samples to fine particles, achieving particle sizes down to the nanometer range. It does this by employing a combination of pressure, impact, and friction. This action results in ultra-fine grinding, ideal for mineral, ceramic, and metallic samples.

Benefits of Vibratory Disc Mills

The versatility of Vibratory Disc Mills is what sets them apart. Besides being able to handle hard, brittle, and fibrous materials, these mills can also deal with materials of varying levels of hardness, moisture, or temperature sensitivity. Additionally, they are renowned for their speedy sample processing and minimized material loss.

Operating Principles of Vibratory Disc Mills

The functioning of a Vibratory Disc Mill relies on two main components: a grinding set and a disc. The grinding set consists of a bowl and a puck. The puck is placed inside the bowl with the sample. As the disc begins to vibrate, it sets the puck in motion. The puck then grinds the sample against the walls of the bowl, effectively reducing the sample size.

Selecting the Best Vibratory Disc Mill

Choosing the right Vibratory Disc Mill depends on a few key factors. You need to consider the material to be processed, sample volume, desired particle size, and your budget. Premium brands offer a variety of options to suit different needs, with quality and durability being at the forefront of their design.

The Future of Vibratory Disc Mills

With advancements in technology, we can expect Vibratory Disc Mills to get even better. Smart features for real-time monitoring, advanced safety protocols, and increased efficiency are all on the horizon. It’s safe to say that Vibratory Disc Mills will continue to play a vital role in laboratory procedures.

Conclusion

For accurate and efficient sample preparation, Vibratory Disc Mills are the go-to equipment. Their adaptability, speed, and precision make them indispensable in a wide array of scientific and industrial applications. Whether you are conducting research or quality control, the right Vibratory Disc Mill can significantly enhance your operations.